How to Build it; Custom Gaming Table

/For the past year and a half, once a week I have a bunch of friends over to my house for a weekly game night where we all get together and play Dungeons and Dragons. Because we're f*%#ing cool. Our group is fairly large with seven players and myself as the dungeon master (I know, I know, hes a dungeon master for a weekly D&D game? Tame the pitter-patter of your fluttering hearts and calm the rush of blood to your nethers, I'm taken). With such a large group, we need quite a bit of space, which for the past 18 months has meant my dining room table.

While everyone does fit around this table, it gets a little elbowy with all seven people plus all of their books and notes and stuff taking up positions around the table. That's before you even account for me with all of my DM shit taking up a chunk of surface area. While that's mostly bearable, the main thing is that between my source books, miniatures, campaign binders, props (yes I have props, I run an immersive game, f*%k you), and other assorted things; when the table is not being used for gaming I have to move approximately 180,000,000 lbs of shit out of there if I want to use the room for anything else.

I decided that it was for the best if I actually set up a space to be a designated game room. We've got a room downstairs in our house where we've been steadily moving all of our hand-me-down/thrift store furniture as we replace it with newer, less decrepit things to the point where it's become this weird hybrid room with a junky dining room set, a couch and chair from 1992 and a terrible rug. Also I accidentally painted it basketball orange so. . .

If we got rid of the garbage furniture, repainted the walls and furnished it with stuff that made some semblance of sense, we could have a really nice game room/place to entertain. The centerpiece and focal point of this room, would of course be the gaming table.

I had an idea what I wanted, which was a fairly simple table, preferably kind of rustic/taverny looking that had removable table-top slats to reveal a gaming pit underneath so that the piece could do double duty as a normal table when not in use for D&D. With my general vision in mind I did some shopping around online, finding that unless I wanted to spend upwards of $1,000 I was out of luck. On top of that, the options I found that were remotely reasonable in cost were not what I was looking for aesthetically speaking.

Now, I won't name any companies specifically, but I'll just say that if i'm going to get a gaming table that is to be considered in any way ultimate, it's sure as sh!t not going to be some Ikea looking piece of crap. If I'm going to have a sh%t gaming table, I'll spend 200 bucks and make it my damned self.

The following is the process of building my custom gaming table, with notes and descriptions of what I did, in case anyone reading is interested in building one for themselves:

The first thing I did was search around on the internet for plans for a gaming table build. Like I said, I had a general idea that I needed a fairly large, rectangular table with a gaming pit set down into the surface and panels of some sort that could be put in and taken out to convert it to a regular table when not in use, no break down of my game setup required.

I found a set of plans that seemed fairly popular for people doing home builds of tables, which I will link to at the end so you can use that as an additional resource if you are trying to recreate this build. The only issues I had with the plans and walkthrough video that the original creator put together was that they were a little vague about certain details, missing measurements in some places and the table he was building was only 4X4, and had a monitor mounted in it. Needing a larger table and not really being a digital map/computer screen kind of DM, some modifications would need to be made, along with a fair bit of just f*#@ing winging it. I never claimed to be a competent carpenter, I think it's important that you remember that.

I went through his plans, watched his walkthrough a couple of times while taking notes, and assembled my materials list based on what I thought I'd need to build his same style table at the dimensions I wanted. Here is what I came up with:

(2x) 1"x6"x8'*

(2x) 1"x6"x6'*

(4x) 1"x4"x8'*

(4x) 1"x4"x4'

(3x) 3/4"x3/4"x6' quarter round

(10x) 2"x4"x8'

(5x) 1"x8"x6*

4'x6'x3/4" plywood

*try to get the higher quality, smoother, straighter cuts of lumber for these items as they are the parts of the table that will be visible, and it's important that they not be warped. It will save you a lot of effort sanding and prepping as well if some of that is done for you.

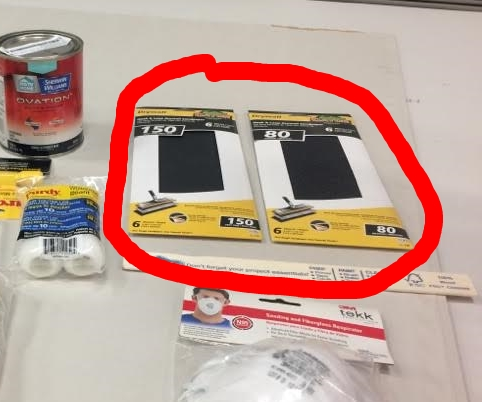

My additional materials list included these items:

Wood glue (large)

Wood filler (stainable)

(8x) 2 1/2" lag bolts

1 5/8" screws

2 1/2" screws

finish nails

120 and 220 grit sandpaper

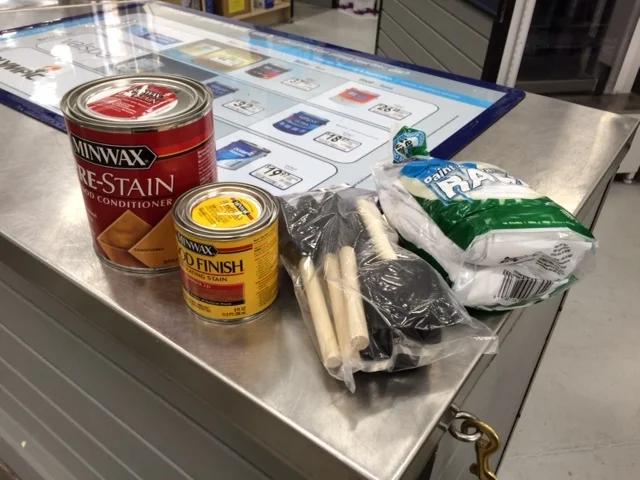

wood stain (color of choice)

wood pre-stain

Spar-Urethane (1g)

Tools I used:

Handheld circular saw

Table Saw

Jig saw

Corded Drill

tape measures, levels, straight edges

Tools that I didn't have but would have been good: Miter saw

I got all my materials and set everything up in the garage. I had an old desk in there that I used to place the plywood on while building the table, but if you have a couple of sawhorses or some other flat surface to work on, whatever will do.

The first thing I needed to decide was exactly what size the table should be. Based on the size of the room I wanted to put it in, and the number of people I needed to comfortably sit around it, I settled on having the play area be 3'x6' with the total dimensions of the table being closer to 4'X7' with the added length and width of the area around the gaming pit that would have cup holders and dice trays set into it

I cut my plywood down to 3X6 with s circular saw. which is the size it is in the picture above.

The basic plan from this point was to build a framework on the underside to make sure the table was nice and sturdy, and then build up and out off the edges of the plywood on the top to create a raised frame around the center.

Next the framing/support for the bottom using 2x4's. In the original design, there was a cutout and mount for a monitor smack in the center of the plywood there, but I wasn't planning on doing that so I added a third support right in the middle to make sure it was nice and sturdy.

The two sides of this 'ladder' looking thing are the exact same length as the plywood, while the horizontal supports are 24 inches and spaced evenly, using the center one at the exact middle of the table as a reference.

WIth everything centered lengthwise and widthwise, I took a pencil and marked the outlines where the supports were and removed them.

I took my drill and pre-drilled holes where the supports would be attached to the plywood. I always try to pre-drill, as it reduces the risk of splitting the wood, or stripping a screw half way in. Especially since I was going to be using 2 1/2" screws for this part the last thing I wanted to do was spend twenty goddamn minutes unscrewing a stripped screw from the board with a pair of pliers.

2 1/2" screws securely drilled in from below, using my pre-drilled holes as a guide, I flipped the table over to get to work on the top portion.

The next step here would be to put on the first piece of framing, what would essentially create the border around the play area (plywood surface).

The original plans recommended a 2 1/2 inch lip above the play area so that there would be enough room to place a tabletop over it without having to remove miniatures and stuff, so I marked 2 1/2 inches on the 1X4's that are used for this part.

This took some figuring as it was poorly marked on the original plans I had, and the walkthrough video didn't cover it, but this framing is done by cutting the two pieces on the long sides of the table so they extend past the end of the table, while the pieces on the short sides sit inside.

You apply a bead of wood glue, line up your 2 1/2" mark with the top edge of the plywood, and secure it with finish nails to hold it in place. You then go back though with 1 5/8" screws and secure it firmly to the plywood.

It looks like this when it's done:

The thing that tripped me up was figuring out exactly how far out the two side pieces needed to stick. What I ended up doing was attaching the two short pieces to the plywood first, since I knew they were exactly the width of the plywood. I then set it on the ground and laid pieces out to mock everything up so I could measure. Essentially, what you are starting here is the framework that the top piece with the cupholders and stuff sits on, the short piece that was just secured being flush with the 1x6 that creates that top.

Long story short if you use the inside corner of the short 1x4 (corner of the plywood) as your starting point, the long board needs to stick out 5" off the end of the table, so that when another 1x4 is later attached flat with the protruding pieces it creates a frame that is 5 1/2 inches wide to fit flush with the 1x6 top piece. (Actual measurement for a 1x6 is really 5 1/2 inches wide, probably for some mathematical reason that makes sense, but I don't understand, so I'm just going with because wood is stupid)

If that was confusing, sorry. It confused the shi%t out of me while I was building the thing, and STILL confused the sh%t out of my trying to re-explain it after I've already done it. Hopefully the pictures going forward will help you understand how it all goes together.

The next thing to do is cut out all these little nubbin boys here. They are made by taking 2X4's, cutting them once to make 5' pieces, and then cutting those lengthwise to shave off about and inch.

These are going to be the braces that go all around the frame we have put up and become supports to make the outer area nice and strong, since that's where people will be leaning. I made 12 of them, and arranged them like this:

The long sides got four each, while the short sides got two. You can kind of see now how those long pieces create two additional supports on the corners. I probably messed this up a little bit with my placement on the long sides with these. I probably should have spaced them out more so that the corners had a support down right at the end just like the short sides do. It all went together fine and seems sturdy, so I guess it's not that big a deal.

To secure these, i put wood glue on the end, pressed it to the 1x4 with the bottoms of both pieces flush with one another then hammered a finish nail in from the inside of the frame to hold it in place and followed it up with a 1 5/8" screw.

This is where stuff started to get a little tricky for me in particular as I didn't have a nice table mounted miter saw for making 45 degree cuts. I was working pretty much exclusively freehand. My hand circular saw did angle to make a 45, but I pretty much had to rely on a steady hand to make it even.

In other words I was f*%#ed at this point.

Using the long pieces of the interior part of the framework as a guide (the shorter edge of the angled cut lined up with the end of the other piece of wood) I made the two of those with the 1x4s and attached them so that I could set my shorter pieces on top and mark where to make my cuts.

I attached these at this point, but you SHOULD NOT. The next step I outline, should be done before you put these pieces in place. It will make your life much easier.

Here it is assembled. The angled pieces get slapped onto the outside of the framework we've created out of our long inner boards and 2x4 nubbies. Two finish nails go into the board at the site of each support with wood glue to seal it all. I also put two nails in each corner to help pull them more flush. Like I said I was freehanding that sh#t, so it didn't come out as perfect as I'd have liked.

Next I put in the quarter round pieces that will serve as a lip for the tabletop to rest on when covering the gaming area. Like I said, I should have done this before attaching the 1x4 to the outside of the frame because it was a nightmare to attach these. I couldn't get a hammer at a correct angle or with enough force to drive finish nails in, so I ended up having to pre-drill holes with my drill, and then hand screw in 1 5/8' screws doing my best not to punch out of the rounded side if I went too far.

The next step was to cut the 1x6's at 45 degree angles across the width to create the top of our outer border. Again, here a mounted miter saw with a swivel would have been nice, but I did it freehand by making a 45 degree angle line in pencil and following it as steadily as possible.

Here it is with three of the four pieces in place. You can finally tell what the finished thing is going to look like here. with the raised area for players to lean, write and place their drinks on, and the lower portion down below for miniatures and maps.

You can also see here I started tracing my cutouts for cupholders.

It was around this time that I changed my mind on putting dice trays in, as I felt they would take too much of the surface area away and leave players feeling a little cramped. With such a large interior play area it would be easy enough to roll in there.

I traced the rim of the cupholders so that I'd be able to cut out the hole with a jig saw slightly smaller. The hole didn't need to be particularly pretty, just wide enough that the cup holder could slip in there and rest on the lip.

The cupholders I got off Amazon, they are the same ones the guy used for his original design. A link to them is in the description of the youtube video I'll put at the end.

Here it is all assembled. I attached the tops of the arm rest portion by putting a bead of glue all the way around the 1x4 frame that I created and setting the piece down before securing it with finish nails. I went in after that with wood filler and patched over my nail holes as well as the seams at the corners where my aformentioned lack of proper tools and general shittiness at carpentry had left it looking slopy.

Next I made the legs.

These were pretty simple 2x4 legs. Each one is made by cutting lengths of 2x4s and screwing them together. One piece is longer, and gets cut to whatever the height you want your table to be is. I went a little higher than the original plans, but you could easily go higher still if you wanted a bartop height gaming table. Whatever you cut the longer piece at, you cut the other part of the leg 3 1/2 inches shorter so that it can slot right up against the ladder shaped frame that was done in the beginning.

Rinse and repeat until you've got four identical table legs, then pre-drill and secure the two halves of the legs to each other. I used three 2 1/2" screws for each leg.

I wouldn't recommend attaching the legs to the table yet, as it will be a lot easier to attach the bottom shelf to them after you make it and then put the thing together in it's final home at the very end.

Next I created the slats to sit inside the lip of the table and create a smooth surface for when it wasn't in use for gaming. I had originally intended to make them horizontal but a friend suggested they would look better as long vertical planks instead. Due to the fact that he was right and also doing long vertical planks meant less cutting I decided to go with that. Whoever said laziness and aesthetic appeal didn't go hand in hand?

To get the 1x8's to fit properly I did still have some cutting to do though, so first I cut them all down to 6ft so they would fit lengthwise. The math wizards in the group might be saying "Hey, isn't that opening 36 inches wide? 8inch planks aren't going to divide evenly into that amount of space".

The math wizards are correct. Five 8' planks, which we all know are really 7.5 inches across because wood is stupid, to fit into the 36inch opening I left four of them alone and cut the fifth piece down to six inches wide using a table saw and set this in as the middle piece.

It's hard to see here, but I cut a hole in the center of that thinner piece so that it could hooked with a finger and lifted out of the center when you were trying to take the cover off.

At this point I wanted a change of pace from measuring, cutting and building, so I decided to leave the bottom shelf for later, and go on to sand stain and finish the parts I had already built.

I used the 120 grit sandpaper to smooth down any rough patches and then switch to the 220 to give everything a once over to get it as smooth as possible, I have an orbital sander, but after doing all of the cutting freehand I had some stupid idea that Id forsake the power tool and sand it all by hand. I do not recommend this it was tiring and took forever.

I used a lighter colored stain, with just a hint of amber tint to it, because I was going for a rustic, well worn tavern table look to go with the D&D concept of the table. It took two coats of stain to get the color the way I liked it.

For the finish I used the Spar-urethane because I did some research, and short of actually building a framework around the table pieces and doing a resin pour, that was the best finish to give that thick glassy bartop look I wanted.

The urethane took three coats to get it nice and solid. I had some trouble with the slats after the urethane went down as the layer added just enough extra size and friction to make them not want to fit. I had to further shave down the center plank little by little until it fit in.

Once it was all dry I popped the cupholders in to see what the finished tabletop would look like. I opted not to secure the cupholders, as they fit in there fairly snugly, and I figured if anyone ever spilled or anything they'd be easier to clean if I could just take them out.

The bottom shelf was surprisingly easy to make. It's just a frame of 2x4s screwed into each other with 2 1/2 inch screws then planks get attached to the top with wood glue and finish nails.

I measured the distance between the insides of the long supports on the underside of the table and made the shelf that exact width and 62 inches long. For the top I used pieces of leftover something I had picked up at some point that was not the size I thought it was (I think they were 8 inches wide by 1 1/2 or something) It turned out I had just enough to perfectly fit the frame I'd made, and the pattern of the alternating depth wood looked cool so I wen't with it. It was either that or go buy more wood, and once again, laziness and aesthetics are not mutually exclusive.

I sanded, stained and finished it the same as I had done with the tabletop and legs, attached the legs to the corners of it from the inside with 2 1/2 inch nails and it was all done.

I attached bottle openers to the four corners of the table top so people could open their beers while we play, and it was all ready to go except for getting it moved inside, assembled, and finishing the play surface on the interior.

I did bring it inside at this point and attached the top to the bottom. For the play surface I decided to use cork. I thought felt would look bad if I tried to put it down myself, and that 5mm craft foam that you see used a lot didn't seem like it would hold up, so I found a roll of 4ft by 6ft cork sheeting that I could cut to size and super glue to the play surface.

If you were following along, doing your own table build, you could call it a day at this point if you wanted to. The table has everything it needs to be a completely low tech solution for your tabletop game. As I said, I'm not really a computer maps and mounted monitor kind of DM so for the most part a nice looking table with some minor bells and whistles pretty well covers my needs.

I did however get a little ambitious with some ideas for some slight upgrades to add a little bit of tech flare to my setup. If none of this other stuff appeals to you, feel free to stop at the above point, but here is a breakdown of a couple of add-ons I made:

The first thing I added was these color changing LED strip lights that I found around the interior border. The lights I found have a little remote control so I can switch them to different hues so I can play around with mood lighting. Red when the party fights the dragon in it's lair full of magma flows? Green when they walk through the sunlit forests of the elves? Pink when the bard starts playing Barry White in the tavern to seduce wenches? You get the idea, I told you I run an immersive game and anyone who says otherwise is a lying son of a b#tch.

I secured them around the interior lip of the play area and drilled a small hole through which to run the power cable out of the table and down the leg.

Last, I decided I wanted to create a piece that would give me (or anyone DMing) extra space at the head of the table for all the assorted stuff they need, so I took a scrap piece of the plywood I'd cut off the table and made a single horizontal plank about a foot wide that I stained and finished. Plywood doesn't really take stain properly the way a normal piece of lumber will so I don't typically recommend it. For me it was the only spare piece of wood I had that was large enough and it was a combination of wanting to make use of what I had if I could and not caring all that much about the appearance since it was only there to get hidden behind the DM screen anyway. Sometimes laziness and aesthetic appeal are in fact, at odds.

If you wanted to do this, it would be a simple matter of getting another board at whatever width you felt was suitable for the DM area.

Here is the finished product, all the bells and whistles added

I put two chairs on each side for the picture here, but it easily fits three to a side with two on each end for a total of eight people comfortably around it. Eventually my plan is to make a pair of benches for the long sides and get a few interesting looking chairs for the ends. Until then, I'm just using chairs from wherever in my house..

All in all I'm pretty happy with the way it came out. It's very sturdy, looks pretty much how I envisioned it, and will suit my gaming needs perfectly.

Now I just have to do something about the rest of the room around it. . .

Link to the youtube video with plans that I followed: here

These can also befound in the description of the video:

Link to the cupholders: here

Link for bottle openers: here

Link for LED's : here (note here: They cost me 24 bucks of a supposed original price of $138. They have an expiration timer on the sale, but it said the same thing when I bought them three weeks ago, so I think it's just bullshit to make you buy them faster.)